+86-574-86597612

+86-574-86597612

| Nominal pertundere diam | Deviatio dmp | Variatio Vdp Series | Variation Vdmp | Taper bore 1:12 Deviatio / Variatio | |||||

| > | <= | dmp | 7.8.9 | 0.1 | 2.3/4 | Vdmp | dmp | d1mp-dmp | Vdp |

| 2.5 10 | 0 -8 | 10 | 8 | 6 | 6 | 15 0 | 15 0 | 10 | |

| 10 18 | 0 -8 | 10 | 8 | 6 | 6 | 18 0 | 18 0 | 10 | |

| 18 30 | 0 -10 | 13 | 10 | 8 | 8 | 21 0 | 21 0 | 13 | |

| 30 50 | 0 -12 | 15 | 12 | 9 | 9 | 25 0 | 25 0 | 15 | |

| 50 80 | 0 -15 | 19 | 19 | 11 | 11 | 30 0 | 30 0 | 19 | |

| 80 120 | 0 -20 | 25 | 25 | 15 | 15 | 35 0 | 35 0 | 25 | |

| 120 180 | 0 -25 | 31 | 31 | 19 | 19 | 40 0 | 40 0 | 31 | |

| 180 250 | 0 -30 | 38 | 38 | 23 | 23 | 46 0 | 46 0 | 38 | |

| 250 315 | 0 -35 | 44 | 44 | 26 | 26 | 52 0 | 52 0 | 44 | |

| 315 400 | 0 -40 | 50 | 50 | 30 | 30 | 57 0 | 57 0 | 50 | |

| 400 500 | 0 -45 | 56 | 56 | 34 | 34 | 63 0 | 63 0 | 56 | |

| 500 630 | 0 -50 | 63 | 63 | 38 | 38 | 70 0 | 70 0 | ||

| 630 800 | 0 -75 | 80 0 | 80 0 | ||||||

| 800 1000 | 0 -100 | 90 0 | 90 0 | ||||||

| 1000 1250 | 0 -125 | 105 0 | 105 0 | ||||||

| 1250 1600 | 0 -160 | ||||||||

| 1600 2000 | 0 -200 | ||||||||

| Nominal Diameter exterior | Deviatio | Variatio Vdp Series | signati portantes | Variation | Radial runout | |||

| > | <= | Dmp | 7.8.9 | 0.1 | 2.3/4 | 2 3 4 | VDmp | Kea |

| 6 18 | 0 -8 | 10 | 8 | 6 | 10 | 6 | 15 | |

| 18 30 | 0 -9 | 12 | 9 | 7 | 12 | 7 | 15 | |

| 30 50 | 0 -11 | 14 | 11 | 8 | 16 | 8 | 20 | |

| 50 80 | 0 -13 | 16 | 13 | 10 | 20 | 10 | 25 | |

| 80 120 | 0 -15 | 19 | 19 | 11 | 26 | 11 | 35 | |

| 120 150 | 0 -18 | 23 | 23 | 14 | 30 | 14 | 40 | |

| 150 180 | 0 -25 | 31 | 31 | 19 | 38 | 19 | 45 | |

| 180 250 | 0 -30 | 38 | 38 | 23 | 23 | 50 | ||

| 250 315 | 0 -35 | 44 | 44 | 26 | 26 | 60 | ||

| 315 400 | 0 -40 | 50 | 50 | 30 | 30 | 70 | ||

| 400 500 | 0 -45 | 56 | 56 | 34 | 34 | 80 | ||

| D 630 | 0 -50 | 63 | 63 | 38 | 38 | 100 | ||

| 630 800 | 0 -75 | 94 | 94 | 55 | 55 | 120 | ||

| 800 1000 | 0 -100 | 125 | 125 | 75 | 75 | 140 | ||

| 1000 1250 | 0 -125 | 160 | ||||||

| 1250 1600 | 0 -160 | 190 | ||||||

| 1600 2000 | 0 -200 | 220 | ||||||

| 2000 2500 | 0 -250 | 250 | ||||||

| Bore Dia. | |||||||

| > | <= | C1(um) | C2(um) | CN(um) | C3(um) | C4(um) | C5(um) |

| -- 24 | 5 15 | 0 25 | 20 45 | 35 60 | 50 75 | 75 100 | |

| 24 30 | 5 15 | 0 25 | 20 45 | 35 60 | 50 75 | 75 100 | |

| 30 40 | 5 15 | 5 30 | 25 50 | 45 70 | 60 85 | 85 110 | |

| 40 50 | 5 18 | 5 35 | 30 60 | 50 80 | 70 100 | 100 130 | |

| 50 65 | 5 20 | 10 40 | 40 70 | 60 90 | 80 100 | 110 140 | |

| 65 80 | 10 25 | 10 45 | 40 75 | 65 100 | 90 125 | 125 160 | |

| 80 100 | 10 30 | 15 50 | 50 85 | 75 110 | 105 140 | 140 175 | |

| 100 120 | 10 30 | 15 55 | 50 90 | 85 125 | 125 165 | 165 205 | |

| 120 140 | 10 35 | 15 60 | 60 105 | 100 145 | 145 190 | 190 235 | |

| 140 160 | 10 35 | 20 70 | 70 120 | 115 165 | 165 215 | 215 265 | |

| 160 180 | 10 40 | 25 75 | 75 125 | 120 170 | 170 220 | 220 270 | |

| 180 200 | 15 45 | 35 90 | 90 145 | 140 195 | 195 250 | 250 305 | |

| 200 225 | 15 50 | 45 105 | 105 165 | 160 220 | 220 280 | 280 340 | |

| 225 250 | 15 50 | 45 110 | 110 175 | 170 235 | 235 300 | 300 365 | |

| 250 280 | 20 55 | 55 125 | 125 195 | 190 260 | 260 330 | 330 400 | |

| 280 315 | 20 60 | 55 130 | 130 205 | 200 275 | 275 350 | 350 425 | |

| 315 355 | 20 65 | 65 145 | 145 225 | 225 305 | 305 385 | 385 465 | |

| 355 400 | 25 75 | 100 190 | 190 280 | 280 270 | 570 460 | 460 550 | |

| 400 450 | 25 85 | 110 210 | 210 310 | 310 410 | 410 510 | 510 610 | |

| 450 500 | 25 95 | 110 220 | 220 330 | 330 440 | 440 550 | 550 660 | |

| 500 560 | 25 100 | 120 240 | 240 360 | 360 480 | 480 600 | 600 720 | |

| 560 630 | 30 110 | 140 260 | 260 380 | 380 500 | 500 620 | 620 740 | |

| 630 710 | 30 130 | 145 285 | 285 425 | 425 565 | 565 705 | 705 845 | |

| 710 800 | 35 140 | 150 310 | 610 470 | 470 630 | 630 790 | 790 950 | |

| 800 900 | 35 160 | 180 350 | 350 520 | 520 690 | 690 860 | 860 1030 | |

| 900 1000 | 35 170 | 200 390 | 390 580 | 580 770 | 770 960 | 960 1150 | |

| 1000 1120 | 50 200 | 220 430 | 430 640 | 640 850 | 850 1060 | 1060 1270 | |

| 1120 1250 | 50 200 | 230 470 | 470 710 | 710 950 | 950 1190 | 1060 1270 | |

| 1250 1400 | 50 200 | 270 530 | 530 790 | 790 1050 | 1050 1310 | 1060 1270 | |

| 1400 1600 | 50 200 | 330 610 | 610 890 | 890 1170 | 1170 1450 | 1060 1270 | |

| 1600 1800 | 50 200 | 380 700 | 700 1020 | 1020 1340 | 1340 1660 | 1060 1270 | |

| 1800 2000 | 50 200 | 400 760 | 760 1120 | 1120 1480 | 1480 1840 | 1060 1270 | |

| Bore Dia. | |||||||

| > | <= | C1(um) | C2(um) | CN(um) | C3(um) | C4(um) | C5(um) |

| -- 24 | 10 20 | 15 40 | 30 55 | 40 65 | 50 75 | 75 100 | |

| 24 30 | 15 25 | 20 45 | 35 60 | 45 70 | 55 80 | 80 105 | |

| 30 40 | 15 25 | 20 45 | 40 65 | 55 80 | 70 95 | 95 120 | |

| 40 50 | 17 30 | 25 55 | 45 75 | 60 90 | 75 105 | 105 135 | |

| 50 65 | 20 35 | 30 60 | 50 80 | 70 100 | 90 120 | 120 150 | |

| 65 80 | 25 40 | 35 70 | 60 95 | 85 120 | 110 145 | 145 180 | |

| 80 100 | 35 55 | 40 75 | 70 105 | 95 130 | 120 155 | 155 190 | |

| 100 120 | 40 60 | 50 90 | 90 130 | 115 155 | 140 180 | 180 220 | |

| 120 140 | 45 70 | 55 100 | 100 145 | 130 175 | 160 205 | 205 250 | |

| 140 160 | 50 75 | 60 110 | 110 160 | 145 195 | 180 230 | 230 280 | |

| 160 180 | 55 85 | 75 125 | 126 175 | 160 210 | 195 245 | 245 295 | |

| 180 200 | 60 90 | 85 140 | 140 195 | 180 235 | 220 275 | 275 330 | |

| 200 225 | 60 95 | 95 155 | 155 215 | 200 260 | 245 305 | 305 365 | |

| 225 250 | 65 100 | 105 170 | 170 235 | 220 285 | 270 335 | 335 400 | |

| 250 280 | 75 110 | 115 185 | 185 255 | 240 310 | 295 365 | 365 435 | |

| 280 315 | 80 120 | 130 205 | 205 280 | 265 340 | 325 400 | 400 475 | |

| 315 355 | 90 135 | 145 250 | 225 304 | 290 370 | 355 435 | 435 515 | |

| 355 400 | 100 150 | 165 255 | 225 345 | 330 420 | 405 495 | 495 585 | |

| 400 450 | 110 170 | 185 285 | 285 385 | 370 470 | 455 555 | 555 655 | |

| 450 500 | 120 190 | 205 315 | 315 425 | 410 520 | 505 615 | 615 725 | |

| 500 560 | 130 210 | 230 350 | 350 470 | 455 575 | 560 680 | 680 800 | |

| 560 630 | 140 230 | 260 380 | 380 500 | 500 620 | 620 740 | 740 860 | |

| 630 710 | 160 260 | 295 435 | 435 575 | 565 705 | 685 835 | 935 975 | |

| 710 800 | 170 290 | 325 485 | 485 645 | 630 790 | 775 935 | 935 1095 | |

| 800 900 | 190 330 | 370 540 | 540 710 | 700 870 | 860 1030 | 1030 1200 | |

| 900 1000 | 210 360 | 410 600 | 600 790 | 780 970 | 960 1150 | 1150 1340 | |

| 1000 1120 | 230 400 | 455 665 | 665 875 | 865 1075 | 1065 1275 | 1275 1485 | |

| 1120 1250 | 230 400 | 490 730 | 730 970 | 960 1200 | 1200 1440 | 1275 1485 | |

| 1250 1400 | 230 400 | 550 810 | 810 1070 | 1070 1330 | 1330 1590 | 1275 1485 | |

| 1400 1600 | 230 400 | 640 920 | 920 1200 | 1200 1480 | 1480 1760 | 1275 1485 | |

| 1600 1800 | 230 400 | 700 1020 | 1020 1340 | 1340 1660 | 1660 1980 | 1275 1485 | |

| 1800 2000 | 230 400 | 760 1120 | 1120 1480 | 1480 1840 | 1840 2200 | 1275 1485 | |

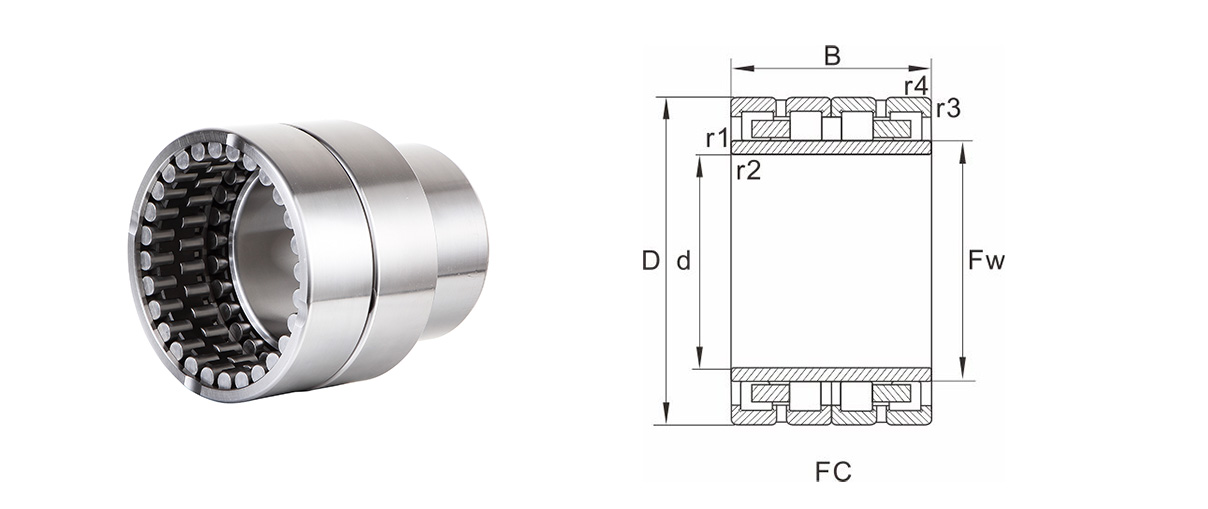

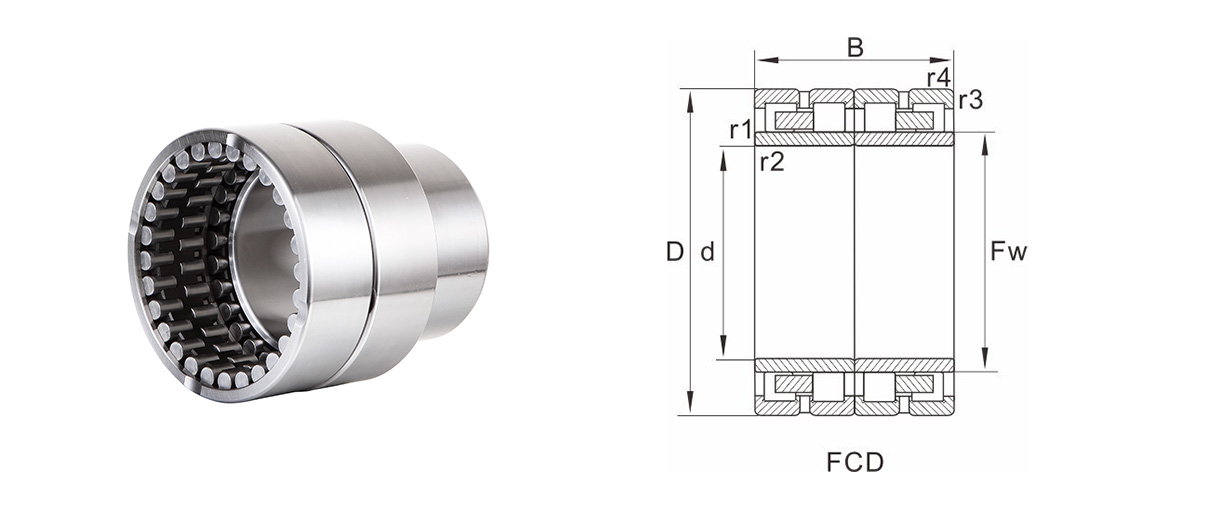

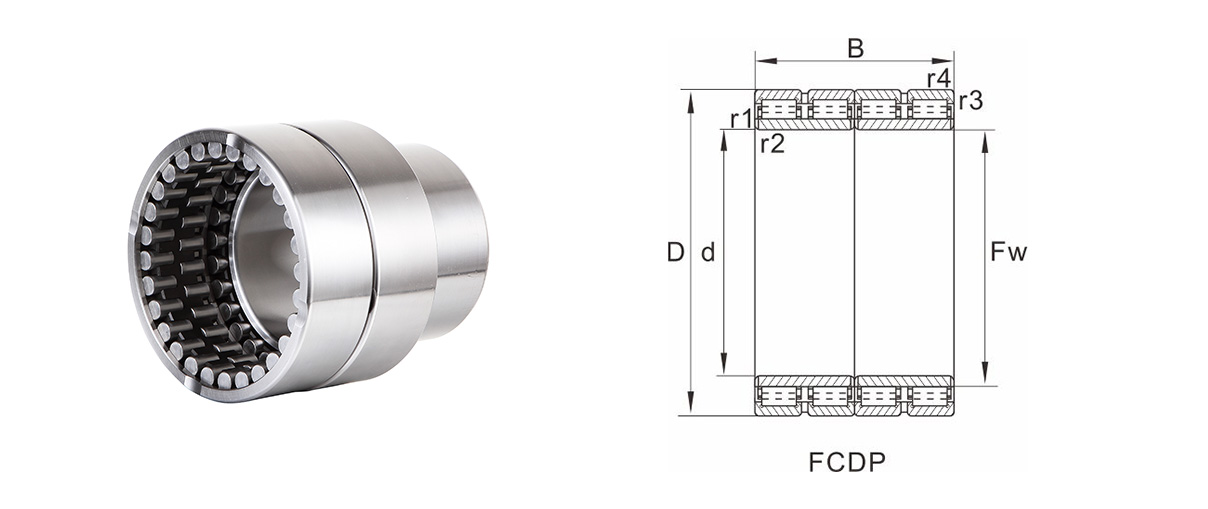

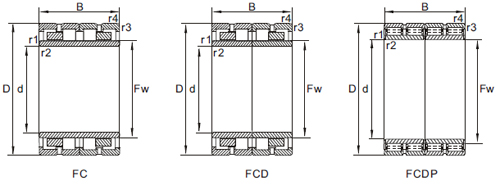

| Mod*el | Dimensiones | rated onus | Pondus | Reference exempla | |||||||||||

designatio | d | D | B | Fw* | r1.2min | r3.4min | Design | Dynamic onus | Static onus | Ref. | SKF | FAG | NTN | NSK | KOYO |

FC110160560 | 550 | 800 | 560 | 610 | 6 | 6 | 4 | 12100 | 28000 | 930 | BC4B322719/HA4 | 517688 | |||

FC112136360 | 560 | 680 | 360 | 590 | 6 | 6 | 1 | 4650 | 16500 | 265 | 4R11202 | ||||

FC1828105 | 90 | 140 | 1405 | 105 | 1.5 | 1.5 | 2 | 402 | 739 | 6 | |||||

FC182870 | 90 | 140 | 70 | 105 | 1.5 | 1.5 | 2 | 242 | 425 | 3.78 | |||||

FC182874 | 90 | 140 | 74 | 105 | 1.5 | 1.5 | 2 | 247 | 485 | 4.2 | |||||

FC202780 | 100 | 135 | 80 | 110 | 1.5 | 1.5 | 2 | 236 | 520 | 3 | |||||

FC2028104 | 100 | 140 | 104 | 111 | 1.5 | 1.5 | 2 | 400 | 820 | 5.3 | 100RV1401 | ||||

FC202870 | 100 | 140 | 70 | 111 | 1.5 | 1.5 | 2 | 238 | 484 | 3.3 | |||||

FC202880 | 100 | 140 | 80 | 111 | 1.5 | 1.5 | 2 | 298 | 610 | 3.8 | |||||

FC202970 | 100 | 145 | 70 | 113 | 1.5 | 1.5 | 2 | 253 | 546 | 3.8 | 20FC1570 | ||||

FC2030106 | 100 | 150 | 106 | 113 | 1.5 | 1.1 | 2 | 480 | 857 | 6.6 | |||||

FC203074 | 100 | 150 | 74 | 115 | 2 | 2 | 1 | 560 | 530 | 4.7 | 4R2035 | ||||

FC2234120 | 110 | 170 | 120 | 127 | 2 | 2 | 1 | 615 | 1100 | 10 | 110RV1701 | ||||

FC223490 | 110 | 170 | 90 | 127 | 2 | 2 | 2 | 376 | 760 | 7.5 | 22FC1790 | ||||

FC223492 | 110 | 170 | 92 | 127 | 2 | 2 | 2 | 380 | 762 | 7.7 | |||||

FC233390 | 115 | 165 | 90 | 132 | 1.1 | 1.1 | 3 | 398 | 750 | 6.5 | 23FC1690 | ||||

FC243387 | 120 | 165 | 87 | 134.5 | 2 | 2 | 1 | 365 | 725 | 6 | 120RV1601 | 24FC1787 | |||

FC243390 | 120 | 165 | 90 | 132 | 2 | 2 | 1 | 510 | 780 | 5.6 | 537675 | ||||

FC2436105 | 120 | 180 | 105 | 136 | 2 | 2 | 1 | 530 | 880 | 9.4 | 4R2438 | 120RV1801 | 4CR120 | ||

FC2436120 | 120 | 180 | 120 | 136 | 2 | 2 | 2 | 678 | 1080 | 11.2 | |||||

FC243692 | 120 | 180 | 92 | 137 | 2 | 2 | 2 | 425 | 797 | 8.01 | 4R2437 | ||||

FC2443102 | 120 | 215 | 102 | 148 | 2.1 | 2.1 | 2 | 710 | 1200 | 16 | |||||

FC2443174 | 120 | 215 | 174 | 147 | 2.1 | 2.1 | 1 | 1060 | 1600 | 27.2 | 120RV2101 | ||||

FC2640104 | 130 | 200 | 104 | 149 | 2 | 2 | 1 | 570 | 950 | 12 | 4R2628 | 130RV2003 | 26FC20104 | ||

FC2640110 | 130 | 200 | 110 | 150 | 2 | 2 | 1 | 608 | 1040 | 12.7 | 26FC20110 | ||||

FC2640125 | 130 | 200 | 125 | 149 | 2 | 2 | 1 | 700 | 1190 | 14.5 | 130RV2001 | 26FC20125 | |||

FC2838119 | 140 | 190 | 119 | 154 | 2 | 2 | 2 | 574 | 896 | 9.7 | 28FC19119W | ||||

FC2842100 | 140 | 210 | 100 | 158 | 2 | 2 | 2 | 605 | 985 | 12.2 | |||||

FC2842106 | 140 | 210 | 106 | 158 | 2 | 2 | 2 | 615 | 1048 | 13 | |||||

FC2842116 | 140 | 210 | 116 | 160 | 2 | 2 | 1 | 640 | 1130 | 13.9 | 4R2823 | 14RV2101 | 28FC21116A | ||

FC2842125 | 140 | 210 | 125 | 158 | 2 | 2 | 2 | 715 | 1265 | 14.9 | |||||

FC2842155 | 140 | 210 | 155 | 158 | 2 | 2 | 2 | 745 | 1330 | 18 | |||||

FC2942155 | 145 | 210 | 155 | 166 | 2 | 2 | 3 | 735 | 1560 | 18 | 314625 | 511605 | 4R2906 | 145RV2101 | 29FC21155 |

FC2945156 | 145 | 225 | 156 | 169 | 2 | 2 | 3 | 835 | 1820 | 23 | 313924A | 538522 | 4R2904 | 145RV2201 | 313924 |

FC2946156 | 145 | 230 | 156 | 169 | 2 | 2 | 2 | 886 | 1827 | 24.7 | |||||

FC3042120 | 150 | 210 | 120 | 166 | 2 | 2 | 2 | 687 | 1080 | 12.5 | |||||

FC3042150 | 150 | 210 | 150 | 165 | 2 | 2 | 1 | 870 | 1780 | 15.9 | 30FC21150 | ||||

FC3044120 | 150 | 220 | 120 | 167 | 2 | 2 | 2 | 702 | 1193 | 15.5 | |||||

FC3044150 | 150 | 220 | 150 | 168 | 2 | 2 | 1 | 900 | 1700 | 19.3 | 4R3031 | 150RGV2201 | 30FC22150A | ||

FC3045120 | 150 | 225 | 120 | 169 | 2 | 2 | 2 | 702 | 1408 | 16.2 | |||||

FC3045136 | 150 | 225 | 135 | 169 | 2 | 2 | 1 | 820 | 1460 | 19 | 150RV2204 | ||||

FC3046130 | 150 | 230 | 130 | 174 | 2 | 2 | 1 | 845 | 1520 | 19.7 | 4R3029 | 150RV2301 | 30FC23130-1 | ||

FC3046150 | 150 | 230 | 150 | 177 | 2 | 2 | 2 | 950 | 1790 | 22.8 | |||||

FC3046156 | 150 | 230 | 156 | 174 | 2 | 2 | 3 | 965 | 1810 | 24 | 313891A | 506962 | 4R3040 | 150RV2302 | 313891-1 |

FC3046168 | 150 | 230 | 168 | 178 | 2 | 2 | 1 | 845 | 1950 | 25.8 | 4R3042 | ||||

FC3050150 | 150 | 250 | 150 | 177 | 2.5 | 2.5 | 1 | 885 | 1640 | 29.6 | 4R3039 | ||||

FC3244180 | 160 | 220 | 180 | 177 | 2.1 | 2.1 | 2 | 940 | 2560 | 2.2 | 4R3224 | 32FC22180 | |||

FC3245120 | 160 | 225 | 120 | 177 | 2.1 | 2.1 | 2 | 639 | 1340 | 14.9 | |||||

FC3246130 | 160 | 230 | 130 | 180 | 2.1 | 2.1 | 3 | 781 | 1340 | 17 | 314190 | 502894A | 4R3226 | 314190 | |

FC3246130A | 160 | 230 | 130 | 178 | 2.1 | 2.1 | 1 | 781 | 1320 | 17.7 | 160RV2301 | 32FC23130 | |||

FC3246168 | 160 | 230 | 168 | 179 | 2.1 | 2.1 | 3 | 1040 | 2170 | 23.5 | 315189A | 510150 | 4R3232 | ||

FC3246168A | 160 | 230 | 168 | 180 | 2.1 | 2.1 | 1 | 1040 | 21700 | 23.5 | 4R3229 | 160RV2302 | 32FC23170A | ||

FC3246180 | 160 | 230 | 180 | 178 | 2.1 | 2.1 | 1 | 1080 | 2270 | 24.6 | 160RV2303 | 32FC23180 | |||

FC3248120 | 160 | 240 | 120 | 183 | 2.1 | 2.1 | 1 | 745 | 1320 | 18.6 | 160RV2401 | 32FC24120W | |||

FC3248124 | 160 | 240 | 124 | 183 | 2.1 | 2.1 | 2 | 750 | 1360 | 19.6 | |||||

FC3248145 | 160 | 240 | 145 | 180 | 2.1 | 2.1 | 1 | 920 | 1600 | 23 | 160RV2403 | ||||

FC3248168 | 160 | 240 | 168 | 183 | 2.1 | 2.1 | 2 | 1042 | 2310 | 26.7 | |||||

FC3248170 | 160 | 240 | 170 | 183 | 2.1 | 2.1 | 1 | 1080 | 2050 | 27.8 | 4R3225 | 160RV2402 | 32FC24170 | ||

FC3446120 | 170 | 230 | 120 | 187 | 2.1 | 2.1 | 1 | 750 | 1580 | 14.3 | 4R3426 | 170RV2301 | 34FC23120 | ||

FC3446130 | 170 | 230 | 130 | 188.5 | 2.1 | 2.1 | 1 | 780 | 1680 | 15.6 | 313673 | 508370 | |||

FC3446160 | 170 | 230 | 160 | 188.5 | 2.1 | 2.1 | 1 | 940 | 2320 | 18.9 | 567622 | ||||

FC3446180 | 170 | 230 | 180 | 186 | 2.1 | 2.1 | 2 | 1040 | 2690 | 24.5 | |||||

FC3448130 | 170 | 240 | 130 | 190 | 2.1 | 2.1 | 3 | 920 | 1830 | 18.7 | BC4B635122 | ||||

FC3448156 | 170 | 240 | 156 | 189 | 2.1 | 2.1 | 2 | 983 | 2070 | 22.2 | 4R3429 | 34FC24156 | |||

FC3448160 | 170 | 240 | 160 | 190 | 2.1 | 2.1 | 1 | 1000 | 2130 | 23 | 4R3423 | 170RV2402 | |||

FC3450150 | 170 | 250 | 150 | 192 | 2.1 | 2.1 | 2 | 980 | 2016 | 25 | |||||

FC3450168 | 170 | 250 | 168 | 192 | 2.1 | 2.1 | 1 | 1020 | 2320 | 28 | 170RV2501 | 34FC25168 | |||

FC3450170 | 170 | 250 | 170 | 192 | 2.1 | 2.1 | 1 | 1180 | 2320 | 28.6 | 170RV2502 | 34FC25170 | |||

FC3451180 | 170 | 255 | 180 | 193 | 2.1 | 2.1 | 1 | 1300 | 2500 | 30.5 | 4R3425 | 170RV2503 | |||

FC3452120 | 170 | 260 | 120 | 195 | 2.1 | 2.1 | 2 | 860 | 1752 | 23 | |||||

FC3452150 | 170 | 260 | 150 | 195 | 2.1 | 2.1 | 1 | 1030 | 1840 | 28.8 | 170RV2602 | 34FC26150 | |||

FC3452170 | 170 | 260 | 170 | 195 | 2.1 | 2.1 | 2 | 1035 | 2096 | 32.7 | |||||

FC3452192 | 170 | 260 | 192 | 195 | 2.1 | 2.1 | 2 | 1090 | 2240 | 36.9 | |||||

FC3452225 | 170 | 260 | 225 | 196 | 2.1 | 2.1 | 2 | 1650 | 3360 | 43.6 | 313587B | 505470 | 4R3431 | ||

FC3650120 | 180 | 250 | 120 | 200 | 2.1 | 2.1 | 2 | 610 | 1578 | 18 | |||||

FC3650130 | 180 | 250 | 130 | 200 | 2.1 | 2.1 | 2 | 716 | 1922 | 19.5 | |||||

FC3650156 | 180 | 250 | 156 | 200 | 2.1 | 2.1 | 1 | 880 | 2230 | 23.4 | 4R3625 | 180RV2501 | 36FC25156A | ||

FC3650156A | 180 | 250 | 156 | 198 | 2.1 | 2.1 | 1 | 880 | 2230 | 23.4 | |||||

FC3650168 | 180 | 250 | 168 | 202 | 2.1 | 2.1 | 1 | 885 | 2470 | 25.6 | 4R3639 | ||||

FC3652120 | 180 | 260 | 120 | 202 | 2.1 | 2.1 | 2 | 735 | 1577 | 21 | |||||

FC3652124 | 180 | 260 | 124 | 202 | 2.1 | 2.1 | 2 | 735 | 1577 | 21.7 | |||||

FC3652156 | 180 | 260 | 156 | 198 | 2.1 | 2.1 | 2 | 835 | 2200 | 27.3 | |||||

FC3652160 | 180 | 260 | 160 | 202 | 2.1 | 2.1 | 2 | 880 | 2230 | 28.4 | |||||

FC365268 | 180 | 260 | 168 | 202 | 2.1 | 2.1 | 3 | 990 | 2300 | 29.5 | 313812 | 507536 | 4R3628 | 180RV2601 | 313812W |

FC3653180 | 180 | 265 | 180 | 204 | 2.1 | 2.1 | 1 | 1040 | 2649 | 33.8 | 4R3618 | 180RV2602 | |||

FC3653180A | 180 | 265 | 180 | 203 | 2.1 | 2.1 | 1 | 1180 | 2395 | 33.7 | 180RV2603 | 36FC27180 | |||

FC3656180 | 180 | 280 | 180 | 206 | 2.1 | 2.1 | 1 | 1287 | 2995 | 41 | 524372 | ||||

FC3656180A | 180 | 280 | 180 | 207 | 2.1 | 2.1 | 2 | 1287 | 2995 | 41.4 | |||||

FC3656200 | 180 | 280 | 200 | 205 | 2.1 | 2.1 | 1 | 1620 | 2990 | 45.7 | 36FC28200 | ||||

FC3852168 | 190 | 260 | 168 | 212 | 2.1 | 2.1 | 3 | 1140 | 2600 | 27 | 313651 | 507735 | 4R3820 | 190RV2601 | 38FC26186-1 |

FC3852168A | 190 | 260 | 168 | 208 | 2.1 | 2.1 | 2 | 1140 | 2520 | 24.9 | |||||

FC3853124 | 190 | 265 | 124 | 213 | 2.1 | 2.1 | 2 | 819 | 1921 | 21 | |||||

FC3854166 | 190 | 270 | 166 | 212 | 2.1 | 2.1 | 2 | 1034 | 2460 | 30.4 | |||||

FC3854168 | 190 | 270 | 168 | 212 | 2.1 | 2.1 | 2 | 1034 | 2460 | 30.8 | |||||

FC3854170 | 190 | 270 | 170 | 213 | 2.1 | 2.1 | 1 | 1240 | 2910 | 31.7 | 4R3818 | 190RV2720 | 38FC27170A | ||

FC3854200 | 190 | 270 | 200 | 212 | 2.1 | 2.1 | 3 | 1510 | 3310 | 37.5 | 314199B | 508657 | 4R3821 | 190RV2701 | 314199 |

FC3856200 | 190 | 280 | 200 | 214 | 2.1 | 2.1 | 3 | 1720 | 3370 | 42 | 314049A | 510199 | 4R3823 | 190RV281 | |

FC4050200 | 200 | 250 | 200 | 215 | 2 | 2 | 2 | 886 | 2360 | 23.2 | 200RV2521 | ||||

FC4053180 | 200 | 265 | 180 | 217 | 2 | 2 | 1 | 1200 | 2790 | 26.9 | 40FC27180 | ||||

FC4054120 | 200 | 270 | 120 | 222 | 2.1 | 2.1 | 2 | 617 | 1630 | 19.6 | |||||

FC4054170 | 200 | 270 | 170 | 222 | 2.1 | 2.1 | 3 | 1170 | 2580 | 28.5 | 314553 | 522742 | 4R4039 | ||

FC4056152 | 200 | 280 | 152 | 222 | 2.1 | 2.1 | 2 | 1000 | 2320 | 29.5 | 4R4054 | 314553 | |||

FC4056170 | 200 | 280 | 170 | 222 | 2.1 | 2.1 | 3 | 1120 | 2300 | 33.5 | 314385 | 507344 | 4R4048 | 40FC28152BW | |

FC4056170A | 200 | 280 | 170 | 223 | 2.1 | 2.1 | 1 | 1120 | 2300 | 33.2 | 549864 | 200RV2804 | 40FC28170 | ||

FC4056188 | 200 | 280 | 188 | 222 | 2.1 | 2.1 | 2 | 1210 | 2720 | 36 | 40FC28188 | ||||

FC4056190 | 200 | 280 | 190 | 223 | 2.1 | 2.1 | 1 | 1350 | 3050 | 37.1 | 4R4024 | 200RV2803 | 40FC28190A | ||

FC4056200 | 200 | 280 | 200 | 222 | 2.1 | 2.1 | 3 | 1410 | 3200 | 39 | 313893 | 508726 | 4R4037 | 200RV2802 | 313893-1 |

FC4056200A | 200 | 280 | 200 | 224 | 2.1 | 2.1 | 1 | 1410 | 3200 | 39.4 | 4R4027 | 200RV2801 | 40FC28200 | ||

FC4058130 | 200 | 290 | 130 | 226 | 2.1 | 2.1 | 2 | 945 | 1916 | 38.5 | |||||

FC4058192 | 200 | 290 | 192 | 226 | 2.1 | 2.1 | 3 | 1410 | 2980 | 42.8 | 313811 | 512580 | 4R4041 | 200RV2901 | 313811 |

FC4058202 | 200 | 290 | 202 | 226 | 2.1 | 2.1 | 2 | 1540 | 3110 | 43.4 | |||||

FC4062130 | 200 | 310 | 130 | 229 | 2.1 | 2.1 | 2 | 1113 | 2254 | 36.3 | |||||

FC4062200 | 200 | 310 | 200 | 229 | 2.1 | 2.1 | 1 | 1670 | 3625 | 55.8 | 524373 | ||||

FC4064216 | 200 | 320 | 216 | 231 | 3 | 3 | 1 | 2120 | 3900 | 69.9 | 4R4028 | 200RV3231 | |||

FC4258192 | 210 | 290 | 192 | 234 | 2.1 | 2.1 | 2 | 1400 | 3240 | 38.2 | |||||

FC4258192A | 210 | 290 | 192 | 236 | 2.1 | 2.1 | 3 | 1400 | 3300 | 41 | 313646 | 507628 | 4R4206 | 210RV2901 | 42FC29192 |

FC4260170 | 210 | 300 | 170 | 234 | 2.1 | 2.1 | 2 | 1320 | 2900 | 38.8 | |||||

FC4260210 | 210 | 300 | 210 | 234 | 2.1 | 2.1 | 2 | 1510 | 3700 | 47.9 | 42FC30210 | ||||

FC4458192 | 220 | 290 | 192 | 239 | 2.1 | 2.1 | 1 | 1190 | 3350 | 33.8 | 4R4413 | ||||

FC4460160 | 220 | 300 | 160 | 245 | 2.1 | 2.1 | 1 | 1050 | 2600 | 32.8 | 4R4419 | ||||

FC4460190 | 220 | 300 | 190 | 240 | 2.1 | 2.1 | 2 | 1220 | 3320 | 39.3 | |||||

FC4460192 | 220 | 300 | 192 | 242 | 2.1 | 2.1 | 2 | 1220 | 3320 | 39.7 | |||||

FC4462190 | 220 | 310 | 190 | 246 | 2.1 | 2.1 | 2 | 1320 | 3450 | 45 | |||||

FC4462192 | 220 | 310 | 192 | 246 | 2.1 | 2.1 | 3 | 1540 | 3450 | 46 | 313239 | 507333 | 4R4426 | 313837A | |

FC4462192A | 220 | 310 | 192 | 247 | 2.1 | 2.1 | 1 | 1540 | 3450 | 46 | 4R4410 | 220RV3101 | 313837-1 | ||

FC4464160 | 220 | 320 | 160 | 245 | 2.1 | 2.1 | 1 | 1200 | 2600 | 46.5 | 4R4428 | ||||

FC4464192 | 220 | 320 | 192 | 246 | 2.1 | 2.1 | 2 | 1600 | 3450 | 51.5 | |||||

FC4468180 | 220 | 340 | 180 | 256 | 3 | 3 | 1 | 1500 | 2750 | 59 | 44FC34180A | ||||

FC4468192 | 220 | 340 | 192 | 246 | 2.1 | 2.1 | 2 | 1820 | 3600 | 64.2 | |||||

FC4666206 | 230 | 330 | 206 | 260 | 2.1 | 2.1 | 3 | 1620 | 3690 | 58 | 313824 | 508727 | 4R4610 | 230RV3301 | 313824 |

FC4666206A | 230 | 330 | 206 | 258 | 2.1 | 2.1 | 1 | 1640 | 3720 | 58.6 | 4R4614 | ||||

FC4668260 | 230 | 340 | 260 | 261 | 2.1 | 2.1 | 1 | 2100 | 4590 | 81 | 4R4611 | 230RV3401 | 46FC34260 | ||

FC4866180 | 240 | 330 | 180 | 265 | 2.1 | 2.1 | 12 | 1460 | 3490 | 49.5 | 635194 | 504547 | |||

FC4866220 | 240 | 330 | 220 | 264 | 2.1 | 2.1 | 1 | 1540 | 3850 | 56.4 | 4R4819 | 48FC33220 | |||

FC4866220A | 240 | 330 | 220 | 270 | 2.1 | 2.1 | 3 | 1500 | 3700 | 58 | 313921 | 508368 | 4R4811 | 240RV3301 | 312943/1YD |

FC4868192 | 240 | 340 | 192 | 268 | 2.1 | 2.1 | 2 | 1474 | 3230 | 55.4 | |||||

FC4868220 | 240 | 340 | 220 | 268 | 3 | 3 | 1 | 1670 | 3530 | 71 | 513703 | 240RV3403 | 48FC34220 | ||

FC4870220 | 240 | 350 | 220 | 270 | 3 | 3 | 2 | 1780 | 3870 | 71 | |||||

FC4872218 | 240 | 360 | 218 | 270 | 3 | 3 | 1 | 2130 | 4060 | 76.8 | 48FC36218 | ||||

FC4872220 | 240 | 360 | 220 | 272 | 3 | 3 | 1 | 1920 | 3920 | 78.8 | 240RV3601 | ||||

FC4872220A | 240 | 360 | 220 | 274 | 3 | 3 | 2 | 1860 | 3900 | 79.6 | |||||

FC496230 | 370 | 480 | 230 | 400 | 4 | 4 | 1 | 2100 | 6250 | 106 | 4R7405 | ||||

FC5065220 | 250 | 340 | 220 | 274 | 3 | 3 | 2 | 1330 | 3120 | 52.8 | |||||

FC5068170 | 250 | 340 | 170 | 274 | 3 | 3 | 2 | 1390 | 3500 | 45 | |||||

FC5070220 | 250 | 350 | 220 | 278 | 3 | 3 | 1 | 1730 | 3990 | 65 | 4R5008 | 250RV3501 | 50FC35220 | ||

FC5070220A | 250 | 350 | 220 | 274 | 3 | 3 | 4 | 1670 | 3640 | 58 | |||||

FC5072220 | 250 | 360 | 220 | 282 | 3 | 3 | 4 | 1810 | 4240 | 73 | |||||

FC5272192 | 260 | 360 | 192 | 288 | 3 | 3 | 2 | 1610 | 3660 | 60 | 52FC36192W | ||||

FC5272200 | 260 | 360 | 200 | 287 | 3 | 3 | 1 | 1880 | 4110 | 62 | 52FC36192W | ||||

FC5272230 | 260 | 360 | 230 | 292 | 3 | 3 | 1 | 1980 | 4200 | 73.5 | BC4B320956 | 533880 | |||

FC5274192 | 260 | 370 | 192 | 291 | 3 | 3 | 2 | 1670 | 4010 | 66 | |||||

FC5274200 | 260 | 370 | 200 | 292 | 3 | 3 | 2 | 1770 | 4120 | 68.9 | |||||

FC5274220 | 260 | 370 | 220 | 292 | 3 | 3 | 3 | 1950 | 4140 | 76.5 | 313823 | 507336 | 4R5208 | 260RV3701 | 313823 |

FC5274230 | 260 | 370 | 230 | 292 | 3 | 3 | 2 | 2020 | 4450 | 79.3 | |||||

FC5276220 | 260 | 380 | 220 | 292 | 3 | 3 | 2 | 2100 | 4900 | 85 | |||||

FC5276280 | 260 | 380 | 280 | 294 | 3 | 3 | 1 | 2420 | 5940 | 108 | 4R5213 | 260RV3801 | 52FC38280 | ||

FC5280300 | 260 | 400 | 300 | 295 | 5 | 5 | 1 | 3900 | 7600 | 145 | 526803 | ||||

FC5374234 | 265 | 370 | 234 | 300 | 3 | 3 | 1 | 2240 | 5400 | 80 | 313922 | 517423 | 53FC37234 | ||

FC5476230 | 270 | 380 | 230 | 298 | 2.1 | 2.1 | 1 | 2000 | 5050 | 81.8 | 270RV3801 | 54FC38230 | |||

FC5476280 | 270 | 380 | 280 | 297 | 2.5 | 2.5 | 6 | 2260 | 5750 | 101 | 4R5407 | ||||

FC5478220 | 270 | 390 | 220 | 306 | 3 | 3 | 4 | 1800 | 4800 | 86.7 | |||||

FC5478220A | 270 | 390 | 220 | 302 | 3 | 3 | 4 | 1800 | 4800 | 85.8 | 54FC39220 | ||||

FC5670208 | 280 | 350 | 208 | 298 | 2.5 | 2.5 | 1 | 1290 | 3950 | 46.4 | 4R5614 | ||||

FC5675200 | 280 | 375 | 200 | 307 | 3 | 3 | 2 | 1500 | 4310 | 63.5 | |||||

FC5676170 | 280 | 380 | 170 | 306 | 3 | 3 | 3 | 1410 | 3590 | 55 | 56FC38170W | ||||

FC5676170A | 280 | 380 | 192 | 308 | 3 | 3 | 2 | 1560 | 4580 | 64.8 | |||||

FC5676192 | 280 | 380 | 192 | 310 | 3 | 3 | 2 | 1560 | 4580 | 64.8 | |||||

FC5678220 | 280 | 390 | 220 | 312 | 3 | 3 | 3 | 2020 | 4400 | 81.54 | 313822 | 507339 | 4R5611 | 280RV3901 | 313822 |

FC5678240 | 280 | 390 | 240 | 312 | 3 | 3 | 1 | 2240 | 5230 | 89.4 | 280RV3902 | ||||

FC5678275 | 280 | 390 | 275 | 312 | 3 | 3 | 1 | 2260 | 6940 | 105 | 513729A | 4R5612 | 56FC38275 | ||

FC5684280A | 280 | 420 | 280 | 323 | 4 | 4 | 1 | 2945 | 7212 | 137 | 4R5605 | ||||

FC5684290/YA3 | 280 | 420 | 290 | 315 | 5 | 5 | 1 | 3900 | 9780 | 140 | 517797 | ||||

FC5878234 | 290 | 390 | 234 | 320 | 4 | 4 | 1 | 2150 | 5320 | 82.2 | 290RV3901 | 58FC39234 | |||

FC5880180 | 290 | 400 | 180 | 320 | 4 | 4 | 1 | 2070 | 5120 | 67.5 | 58FC40180W | ||||

FC5882240 | 290 | 410 | 240 | 320 | 4 | 4 | 1 | 2440 | 5180 | 101 | 4R5806 | 290RV4101 | 58FC41240 | ||

FC5884300 | 290 | 420 | 300 | 327 | 4 | 4 | 1 | 3130 | 7130 | 141 | 4R5805 | 290RV4201 | 58FC42300 | ||

FC5888310 | 290 | 440 | 310 | 328 | 4 | 4 | 1 | 4130 | 9210 | 171 | 517796 | ||||

FC6084218 | 300 | 420 | 218 | 332 | 4 | 4 | 3 | 2014 | 4950 | 94 | |||||

FC6084240 | 300 | 420 | 240 | 332 | 4 | 4 | 3 | 2540 | 5460 | 111 | 4R6027 | 300RV4201 | 60FC422240 | ||

FC6084240A | 300 | 420 | 240 | 334 | 4 | 4 | 1 | 2540 | 5460 | 114 | 4R6012 | ||||

FC6084240A | 300 | 420 | 240 | 336 | 4 | 4 | 1 | 2010 | 5450 | 105 | 4R6023 | ||||

FC6084300 | 300 | 420 | 300 | 334 | 4 | 4 | 1 | 2900 | 7850 | 130 | 4R6015 | ||||

FC6086240 | 300 | 430 | 240 | 338 | 4 | 4 | 1 | 2720 | 5950 | 115 | 60FC43240 | ||||

FC6092270 | 300 | 460 | 270 | 344 | 4 | 4 | 1 | 2670 | 5800 | 162 | 4R6019 | ||||

FC6284300 | 310 | 420 | 300 | 338 | 4 | 4 | 1 | 3130 | 7650 | 121 | 310RV4201 | 62FC42300 | |||

FC6286240 | 310 | 430 | 240 | 344.5 | 4 | 4 | 1 | 2480 | 5650 | 109 | 4R6202 | 310RV4301 | 62FC43240 | ||

FC6490240 | 320 | 450 | 240 | 358 | 4 | 4 | 1 | 2620 | 5840 | 121 | 4R6411 | 320RV4501 | 4CR320 | ||

FC6490240A | 320 | 450 | 240 | 355 | 4 | 4 | 1 | 2600 | 5750 | 116 | 320RV4502 | 64FC45240 | |||

FC6492340 | 320 | 460 | 340 | 360 | 4 | 4 | 3 | 3350 | 8950 | 178 | 4R5412 | 64FC46340A | |||

FC6686230 | 330 | 430 | 230 | 358 | 4 | 4 | 1 | 2220 | 5560 | 89.6 | 330RV4301 | ||||

FC6688200 | 330 | 440 | 200 | 360 | 4 | 4 | 2 | 2050 | 4510 | 85 | 4R6603 | 330RV4401 | 66FC44200W | ||

FC6890250 | 340 | 450 | 250 | 371 | 4 | 4 | 1 | 2580 | 6400 | 111 | 340RV4502 | 68FC45250BW | |||

FC6890250A | 340 | 450 | 250 | 368 | 4 | 4 | 2 | 2580 | 6410 | 111 | |||||

FC6896280 | 340 | 480 | 280 | 374 | 4 | 4 | 2 | 3120 | 8120 | 160 | |||||

FC6896300 | 340 | 490 | 300 | 377 | 4 | 4 | 1 | 3350 | 8300 | 187 | 4R6804 | ||||

FC6896300A | 340 | 490 | 300 | 380 | 4 | 4 | 1 | 3500 | 7600 | 187 | 68FC49300 | ||||

FC72102370 | 360 | 510 | 370 | 400 | 4 | 4 | 1 | 4250 | 9600 | 241 | 4R7212 | 360RV5101 | 72FC51370 | ||

FC72102400 | 360 | 510 | 400 | 397 | 4 | 4 | 2 | 4500 | 11500 | 260 | 4R7203 | ||||

FC7296290 | 360 | 480 | 290 | 392 | 4 | 4 | 1 | 3470 | 8510 | 145 | 72FC48290 | ||||

FC7296290A | 360 | 480 | 290 | 394 | 4 | 4 | 1 | 3080 | 7470 | 149 | 360RV4801 | ||||

FC74108400 | 370 | 540 | 400 | 415 | 4 | 4 | 1 | 4990 | 11400 | 320 | 370RV5401 | 74FC54400A | |||

FC7496250 | 370 | 480 | 250 | 385 | 3 | 3 | 2 | 2820 | 7320 | 115 | 72FC48250W | ||||

FC7496250 | 370 | 480 | 250 | 401 | 4 | 4 | 1 | 2690 | 6980 | 120 | 4R7408 | 370RV4801 | |||

FC76100290 | 380 | 500 | 290 | 414 | 4 | 4 | 1 | 3010 | 7920 | 153 | 380RV5001 | ||||

FC76104280 | 380 | 520 | 280 | 417 | 4 | 4 | 1 | 3280 | 7600 | 174 | 4R7605 | 380RV5202 | 76FC52280 | ||

FC76104290 | 380 | 520 | 290 | 418 | 4 | 4 | 1 | 3380 | 7970 | 181 | 576360 | 380RV5201 | 76FC52290 | ||

FC76108400 | 380 | 540 | 400 | 424 | 5 | 5 | 2 | 4790 | 11400 | 288 | 4R7613 | 380RV5401 | 76FC54400CW | ||

FC76112325B | 380 | 560 | 325 | 428 | 4 | 4 | 1 | 4970 | 10600 | 265 | BC4B322264/HB1 | ||||

FC78102290 | 390 | 510 | 290 | 424 | 4 | 4 | 1 | 3230 | 8550 | 156 | 390RV5101 | ||||

FC80104250 | 400 | 520 | 250 | 432 | 5 | 5 | 2 | 3000 | 7700 | 140 | 400RV5202 | 80FC52250W | |||

FC80108420 | 400 | 590 | 420 | 450 | 5 | 5 | 1 | 5150 | 1300 | 399 | 4R8011 | ||||

FC80110300 | 400 | 550 | 300 | 441 | 5 | 5 | 1 | 3940 | 9260 | 216 | 400RV5501 | ||||

FC84112280 | 420 | 560 | 280 | 457 | 5 | 5 | 1 | 3800 | 9250 | 196 | 4R8403 | 420RV5601 | 84FC56280 | ||

FC84116230 | 420 | 580 | 230 | 466 | 4 | 4 | 1 | 2430 | 6250 | 181 | 4R8408 | ||||

FC84124400 | 420 | 620 | 400 | 478 | 5 | 5 | 1 | 500 | 13400 | 410 | 4R8401 | ||||

FC88118270 | 440 | 590 | 270 | 482 | 5 | 5 | 3 | 3620 | 8460 | 207 | 88FC59270W | ||||

FC92124400 | 460 | 620 | 400 | 506 | 5 | 5 | 1 | 5500 | 14700 | 352 | 460RV6201 | ||||

FC96120236 | 480 | 600 | 236 | 510 | 3 | 3 | 1 | 2620 | 7850 | 155 | 4R9610 | ||||

Anni Usus Opus

Mos muneris

Technology patented

Ningbo DHK Precision Bearing Co., Ltd. ("DHK" pro brevi) specialist inceptis in R&D versatus est, factorum et venditio gestuum, sita est in Ningbo Zhenhai Zonam oeconomicam cum opportuno translatione. Cum institutio per decennium, "technologia", "qualitas" et "officium", semper primae quaestiones in mente nostra causa evolutionis fuerunt. Certos fructus et speciales nativus operas praebemus pro global conatibus in gravibus industriae et satisfactionem obtinuit et bonam famam plurium inceptorum domi militiaeque consecutus est.

DHK maxime producit cylindros gestus, cylindrus conicos gestus, cylindrus gestus auto-adnexos, gestus globulos, ac varios gestus et gestus non-commodus cum superficie specialiter tractatis. Hactenus DHK gestae in talibus campis late applicatae sunt ut machinae machinariae, sentinae industriae, instrumentum machinae, machinae compressionis, casus calces, vis venti et metallurgia in regionibus Europaeis et Americanis exculta.

DHK locus mensurae et inspectionis locus gestus in industria habet et apparatum inspectionis summae totius mundi induxit et systema QC in Sinis constituit, ita ut productum qualitatem in omni rotunditate firmans.

2024-12-02 Industria News

2024-11-25 Industria News

2024-11-18 Industria News

2024-11-11 Industria News

2024-11-04 Industria News

2024-10-28 Industria News

2024-10-21 Industria News

Contact Us And Get A Quote Priority To Learn About Our New Prod!